At CETIA, we are developing solutions to transform textile and leather articles into sources of material ready for recycling. Leveraging automation, robotics and artificial intelligence, we are building efficient systems to make recycling operations competitive. We support marketers, collectors/sorters and recyclers in the design and deployment of innovative solutions to bring their textile and leather recovery projects to life.

Innovation platform dedicated to the recyclability of textile and leather articles

OFFER

PROTOTYPING

INNOVATION

- Removing technological barriers.

- Developing proofs of concept.

- Designing intelligent solutions.

DEMONSTRATING

THE INDUSTRIAL FEASIBILITY

- Studing the technical feasibility on an industrial scale.

- Developing pilot lines.

- Launching pre-production runs.

TRANSFERING

SOLUTIONS TO CUSTOMERS SITES

- Deploying technological solutions.

- Transfering core competence and skills.

- Facilitating the implementation of industrial sites in territories.

WORK AREAS

Identification

Establishing the identity of the product to orient it to the right dismantling process.

Dismantling

Deconstructing a product to separate the materials for their recycling.

Detection

Determine the composition and colour of materials.

Sorting

Automatically orientating materials based on their composition and colour.

Preparation

Enabling materials to be processed by recovery centres.

LINES

EQUIPMENT

Since 2023, the first CETIA equipment are available in HENDAYE (64) in a 1,200 m² building entirely dedicated to innovative solutions for textile and leather preparation operations.

SORTING

TO SORT TEXTILES BY

COMPOSITION AND COLOUR

- VALVAN FIBERSORT machine.

- Composition, colour detection.

- NIR and RGB technologies.

- 1 garment / second.

- 10 sorting bins.

FRAYING

TO MECHANICALLY ISOLATE

THE FIBRES OF THE GARMENTS

- 2 openers and 1 CLEANING WILLOW system from DELL’ORCO Y VILLANI.

- Separation of fibres and trims.

- Pre/post-consumer garments.

- 600 kg / hour.

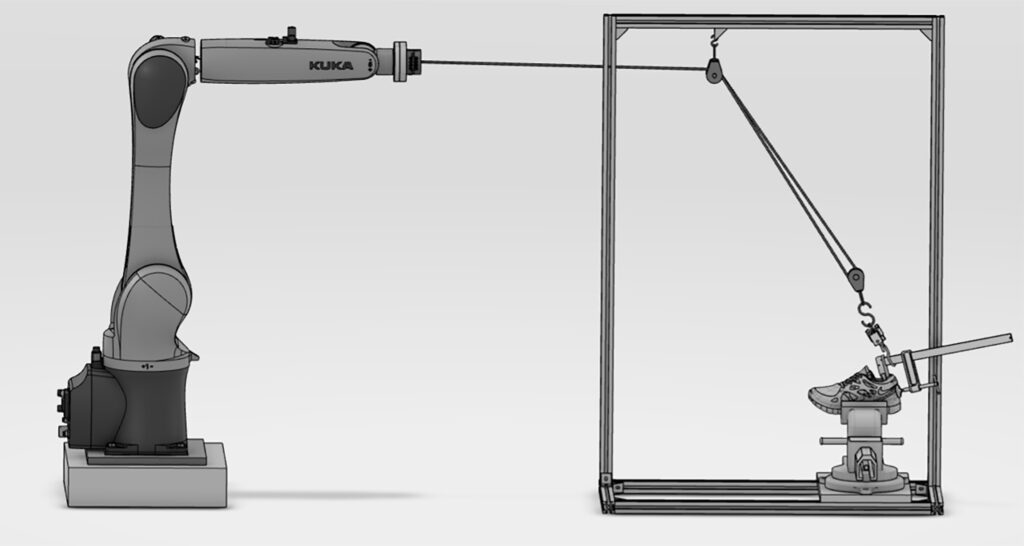

SEPARATE

TO AUTOMATICALLY SEPARATE

AND SORT SHOE SOLES

- CETIA proprietary systems.

- Leisure, sport and luxury shoes.

- Glued, sewn, injected and vulcanised soles.

- 120 shoes / hour (to date).